Uzbekistan to Build Central Asia’s Largest Ethanol Refinery

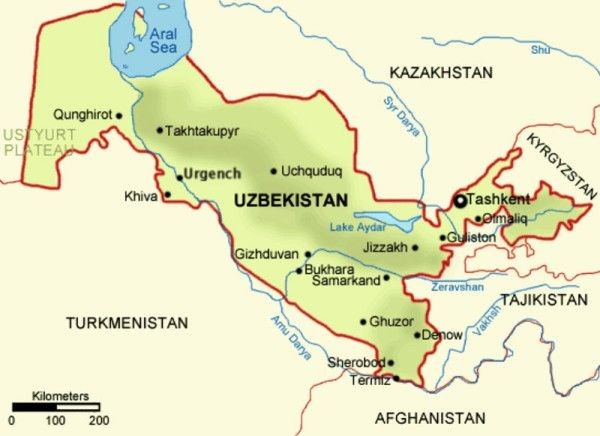

Allied Biofuels FE LLC and India’s Praj Industries Ltd have signed a Memorandum of Understanding (MOU) to construct what is set to become Central Asia’s largest ethanol refinery in Uzbekistan’s Khorezm region, the companies announced on November 17. Praj will provide first-generation ethanol technology, proprietary equipment, and full-spectrum support, including design, engineering, procurement, and commissioning. The planned facility will produce 890 tonnes of 95% ethanol per day, or approximately 293,700 tonnes annually, using sorghum as the primary feedstock. The plant will also capture biogenic CO₂ generated during the production process. Allied Biofuels intends to convert this ethanol into 160,400 tonnes of Sustainable Aviation Fuel (SAF) and 5,040 tonnes of green diesel each year. Biogenic CO₂ will also be combined with synthesis gas and green hydrogen, produced from 2,000 MW of PEM electrolysers, to generate 257,000 tonnes of Electro-Sustainable Aviation Fuel (e-SAF) annually. The project represents the first phase in establishing Central Asia’s first integrated refinery for SAF, e-SAF, and green diesel. According to the companies, the initiative supports Uzbekistan’s climate objectives and aligns with the goals of the national Net Zero Emissions Office. “This MOU is a landmark moment for Uzbekistan and for Central Asia’s clean-energy future,” said Alfred Benedict, Chairman and Managing Director of Allied Biofuels. “This project will strengthen energy security, reduce emissions, and create long-term economic opportunities for the region.” Praj Industries Chairman Dr. Pramod Chaudhari added, “With our proven expertise and advanced technologies, Praj will help develop the ethanol facility and support Uzbekistan in advancing its sustainability targets.” The investment is expected to generate hundreds of skilled jobs and position Uzbekistan as a regional leader in advanced biofuels. The Times of Central Asia has previously reported on Uzbekistan’s increased emphasis on renewable energy and efforts to attract international clean-technology partnerships.