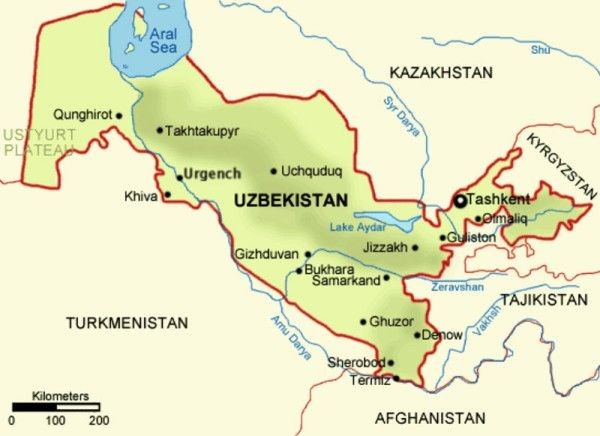

Despite being approved back in 2017, the construction of a hospice for adults in Tashkent remains but a dream. Deprived of palliative care for the past five years, Uzbek citizens afflicted by oncological, haematological, neurological and immunological diseases have been left to suffer and die. Tasked with building the facility, the Comfort Engineering Group has defended the long delay by citing a lack of funds. Although allocated $1.4 million for the build, the company received only $113.5 thousand and as a consequence, was forced to down tools. The city administration had promised to finish the "long construction" back in November 2023 and in April this year, the hospice was expected to receive its first patients. Frustrated by the Uzbek capital's authorities, Yakhyo Ziyayev, oncologist and long-term campaigner for the development of palliative and hospice care in Uzbekistan, stated on social media, "I can honestly tell you, I'm losing faith in the possibility of changing anything for the better in this country. Here comes April. Where is the fulfilment of the promise? A week ago, Rustam (oncologist Rustam Norboev) and I visited the site. Nothing has started. We were told that it would start on Monday, next week. It's OK if they finish late, it's still a victory for us, so I didn't take it negatively." Local specialists have also voiced their disappointment, "Stephen Connor, head of the World Association for Hospice and Palliative Care, is due to visit Uzbekistan in May. But his visit will be pointless because of the lack of basic infrastructure." As a result of the high profile afforded to the oncologist's appeal, the Tashkent khokimiyat has now promised to discuss the issue with the city's recently appointed khokim, Shavkat Umurzakov, within 10-15 days. "If it is not possible to (secure) money to complete the hospice, they will get it from other sources and complete the hospice by September," assured an administration spokesperson. Thanks to the efforts of the Ezgu Amal Charitable Foundation, Israeli Ambassador to Uzbekistan Zehavit Ben-Hillel, Embassy employee Daphne Kfir-Furman and sponsors, Uzbekistan's first and only children's hospice opened in August 2022, has treated 260 patients to date.