BISHKEK (TCA) — After Kyrgyzstan’s accession to the Eurasian Economic Union, orders to local clothing enterprises have increased, the Kyrgyz Association of Light Industry (Legprom) said at a meeting to discuss the challenges facing the garment industry.

Statistics differ

The Association did not agree with the official data. According to the National Statistics Committee of Kyrgyzstan, the textile production has decreased by 30.3% and clothing production by 15.8% from January to September 2016. The financial crisis in the EEU partner countries, especially in Kazakhstan and Russia, was cited as the main reason for the decrease.

Although the US dollar appreciation and depreciation of the Russian ruble against the Kyrgyz som affected Kyrgyz exports, almost all the companies belonging to the Association now have orders for several months in advance and local products are in great demand in the markets of neighboring countries, the Legprom said.

According to Prime Minister of Kyrgyzstan Sooronbai Jeenbekov, the inaccuracy in the statistics was due to the imperfection of the methodology of accounting of products exported to and from the EEU member countries.

Enjoying benefits

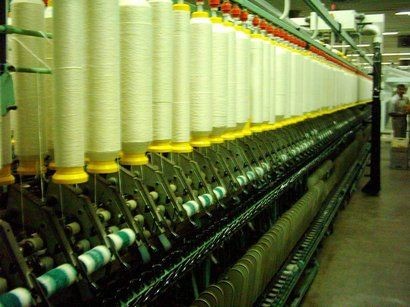

The textile and clothing industry that unites small and medium-sized enterprises is a priority in Kyrgyzstan, with the highest export potential after gold and food products.

According to the Association, Kyrgyz sewing companies have benefited from Kyrgyzstan’s entry into the EEU. The cost of fabrics imported to Kyrgyzstan has increased only by 7-8% while there are now no customs procedures at the border and delivery of goods to Russia has become one day shorter. Freight forwarders have reduced the cost of delivery of clothes from Kyrgyzstan to Russia by half.

Some Kyrgyz garment companies have signed contracts with Russian trading companies with monthly orders of 10 thousand pieces of products and more. For instance, the Textiles Trans factory exports socks and hosiery products to Russia and Kazakhstan, and the Asan sewing company exports menswear to these countries.

The trade promotion program to support the garment and textile industry implemented by the International Trade Centre in cooperation with the Swiss Government helps train local producers in management, marketing, and clothes design. The program includes 175 garment enterprises, and half of them have taken part in international exhibitions.

Unresolved issues

At the same time, the garment industry faces problems which cannot be solved without assistance from the State. Since 2012, the Government has been discussing the idea to create the Sewing Technopolis, an industrial zone that will unite and support small sewing workshops.

The Technopolis could unite garment and knitwear companies, which could create more than 10,000 jobs. To enable producers to sell in foreign markets, the ISO 90001 international quality standard was planned to be introduced in the Technopolis.

Most apparel businesses do not have their own premises, and the rented premises are often not suitable for production, while construction of the Technopolis could push for development of the industry. Increased communication within the Technopolis will reduce the cost to companies. There will also be showrooms where customers will be able to view and purchase goods.

The industry also suffers from limits on the electricity consumption and the shortage of skilled workers and working capital. After the opening of borders with the EEU countries, Kyrgyz citizens can easily find legal jobs in Kazakhstan and Russia. The Association hopes that with time, Kyrgyzstan citizens will prefer working at home, as they will be able to earn the same money here.

The Prime Minister promised to create the best possible conditions for the industry, including low-interest loans from the Kyrgyz-Russian Development Fund.

Modernization

Earlier, local sewing companies sold their products at Bishkek’s Dordoi market, the largest in Central Asia. Merchants from Russia and Kazakhstan bought ready products in bulk and took them to their home countries. Now the Russians do not need to go to the Dordoi to select models of clothes available because they can do it online. Clothing production has also modernized and now uses computer technology.

However, local buyers still perceive domestic production as cheap and low-quality, while local producers claim their products can compete not only with Belarusian and Russian but also Turkish garment.

Local producers are aimed at saving money on everything that does not affect the quality of goods in order prices of their ready-made clothes was affordable to local shoppers. Garment produced for Kyrgyzstan should not be expensive, because most of the population is far from being rich, and people want to spend their money frugally.

To better adapt to increasing competition, the apparel companies need better knowledge of the market, administrative and operational management skills, and better access to financial resources.